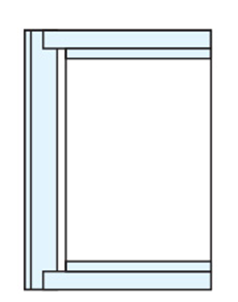

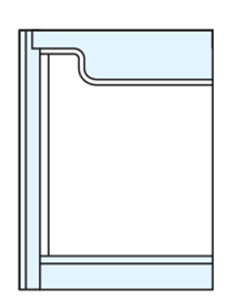

Supported Packaging Formats

Specifications

| Standard (4 Division Type) | 3 / 6 Division Type | Large Capacity | |

| Type | Option to fit Twin Lane 4 Side Seal Type | ||

| Line Speed | 4 – 30 m/min | ||

| Sealing Pitch | 40 – 160mm | 70 – 180mm (3 Division) |

40 – 160mm (Standard) 100 – 250mm (Large 1) 100 – 250mm (Large 2) |

| 30 – 90mm (6 Division) | |||

| Filling Volume | 3g – 100g | 1.5g – 100g |

5g – 100g (Standard) 5g – 350g (Large 1) 5g – 500g (Large 2) |

| Filling volume varies with Twin Lane 4 Side Seal Option | |||

| Maximum Output | 400 pcs / min | 500 pcs / min (6 Division) |

400 pcs / min (Standard) 150 pcs / min (Large 1) 60 pcs / min (Large 2) |

| The output will be doubled with the Twin Lane 4 Side Seal Option | |||

| Dimensions | W 1450mm ✕ D 980mm ✕ H 2200mm | ||

| Mass | ~1,350kg | ||

| Utilities Required |

Electricity: AC 200V ±20V 4.8kVA Air Pressure: 5 bar |

||

Lorem ipsum dolor sit amet consectetur.

Lorem ipsum dolor sit amet consectetur Lorem ipsum dolor sit amet consectetur .

- Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur

Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet consectetur Lorem ipsum dolor sit amet consectetur . Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur /li>

- Lorem ipsum dolor sit amet consectetur

- Lorem ipsum dolor sit amet consectetur

Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit amet consectetur Lorem ipsum dolor sit amet consectetur . Lorem ipsum dolor sit amet consectetur

"Lorem ipsum dolor sit amet consectetur Lorem ipsum dolor sit amet consectetur Lorem ipsum dolor sit amet consectetur"

- Lorem ipsum dolor sit amet consectetur

EN

EN

TH

TH